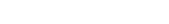

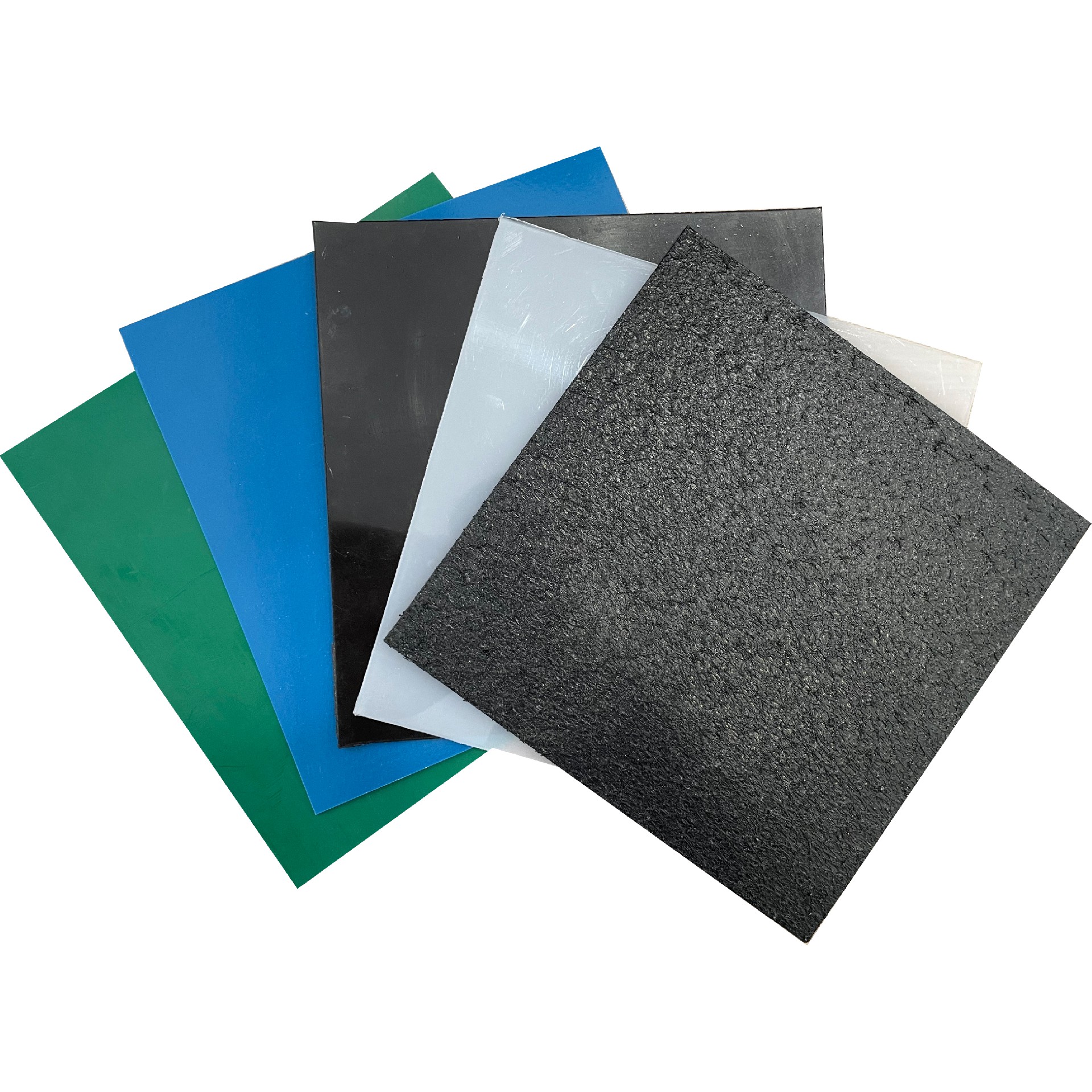

Geotextile is usually made from a synthetic polymer such as polypropylene (PP), polyester (PET) etc. raw material and processed by woven & needle punched non woven or heat bonded methods. It is used as protection, filtration or separation layer alternative to diverse terrain such as soil, rock, sand and so on, also the UV Resistance and Thermal Bonded etc.

The non-woven geotextile is made of filament or short fiber laid into a network through different equipment and processes. After needle punched and other processes, different fibers are interwoven and intertwined to make the fabric standardized,soft, full, thick and hard, so as to meet the requirements of different thickness.

The non-woven geotextile has good fabric gap and good adhesion due to the softness of the fiber, it has certain tear resistance, good deformation adaptability, and good plane drainage capacity. The surface is soft and multi gap, and has a good friction coefficient, which can increase the adhesion capacity of soil particles, prevent the loss of particles by preventing the loss of particles, and eliminate the excess water. The surface is soft and has good protection ability. According to the length of filament, it can be divided into filament non-woven geotextile or short filament non-woven geotextile. They can play a very good filtration, isolation, reinforcement, protection and other effects, is a widely used geosynthetics. The tensile strength of filament is higher than that of staple, so it can be used according to specific requirements.

Non-woven geotextiles are multi-purpose fabrics that are felt-like in appearance. The important functions for this merchandise are filtration and separation. The most frequent non-woven is a needle-punched product. Staple fibers or continuous filaments are bonded via automatically entangling the fibers with barbed needles. It can save installation time is an economical alternative to other geosynthetics. The raw material offers the most cost-effective range of geotextiles bringing the maximum value to your project, this range of non-woven geotextiles offers excellent energy absorption characteristics as well as superior filtration performance.

Specification:

Width: 1-6m

Length: 50-300m as customized

Weight:100-1200g/㎡

Color: as customized

1.Water conservancy project and hydropower project

2.Road paving, railway

3.Airport and port

4.River bank protection and tunnel

5.Environmental protection, etc

Separation means using geotextiles to separate building materials (such as soil and sand, sand and gravel, soil and concrete, etc.) with different physical properties (large grain size, distribution, consistency and density, etc.). The two kinds of materials are not lost or mixed, the overall structure and function of the materials are maintained, and the load bearing capacity of the structure is strengthened.

Filtration When water flows from the fine soil layer into the coarse soil layer, the good air permeability and water permeability of the needle-punched geotextile are used to allow the water to pass through, and the soil particles, fine sand, small stones, etc. can be effectively intercepted to maintain the water and soil The stability of the project.

Drainage Needle-punched geotextile is a good water-conducting material. It can form a drainage channel inside the soil and drain the excess liquid and gas from the soil structure.

Reinforcement the use of needle-punched geotextiles to enhance the tensile strength and deformation resistance of the soil, increase the stability of the building structure, and improve the quality of the soil.

Protection Effectively diffuse, transfer or decompose the concentrated stress to prevent the figure body from being damaged by external forces.

Waterproof needle-punched geotextile is combined with other materials (mainly asphalt or plastic film) to form an impermeable barrier in the soil layer. (Used for road resurfacing and repairing, etc.)

Dezhou Huaxiang New Material Technology Co., Ltd.

HuaXiang had been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2011. Huaxiang had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 36 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

HuaXiang is not only manufacturing best quality geosynthetics products but also providing professional design and installation service. OEM, ODM, Custom development and fabrication are also available. If you have any questions or inquiries, please fill out the form. we will reply as soon as possible.